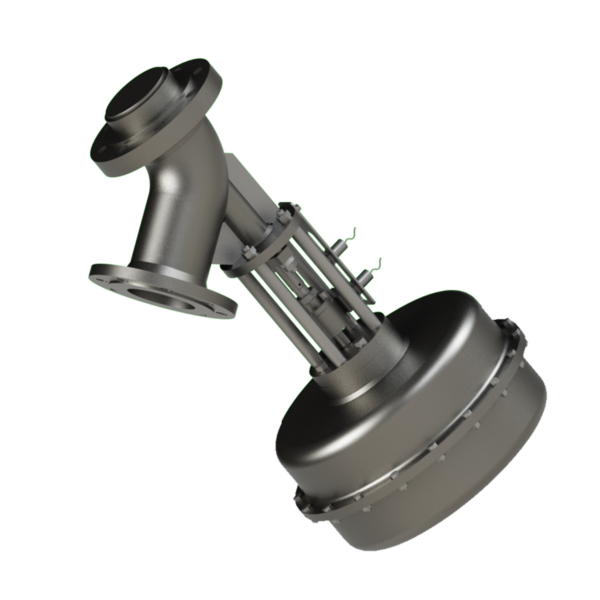

Tank bottom valve

Tank bottom valve

Tank or reactor bottom outlet valve

see moreDN

20 à 400

NPS

3/4 à 16

PN

10 à 250

Class

150 à 1500 Lbs

brand(s)

CONTACTER L’ÉQUIPE COMMERCIALEFunctions

VALCO GROUP offers you specific valves intended for emptying at the bottom of the tank / reactor.

Tank or reactor bottom outlet valve

Tank bottom control valve

Utilisation

CONDITIONS DE SERVICE

High pressure, High temperature, Low temperature, Abrasion, Corrosion, Vacuum

TYPES OF FLUIDS

Liquids, Liquids with solid particles, Gas, Powder and powdery media, High viscosity fluids

APPLICATIONS

Caractéristiques

SEALING SYSTEM

♦ Disc sealing by PTFE-to-metal contact for a service temperature up to 180°C or by metal-to-metal contact.

♦ Tank connection by means of counter flange

♦ External tightness by means of bellows (see options list)

OPERATION

- Handwheel,

- Gearbox, Double acting pneumatic actuator,

- Single acting pneumatic actuator,

- Hydraulic actuator,

- Electric actuator

CLOSING DEVICE

Disc