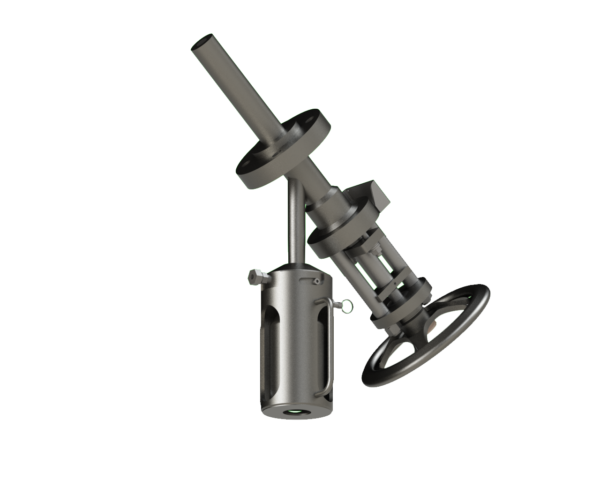

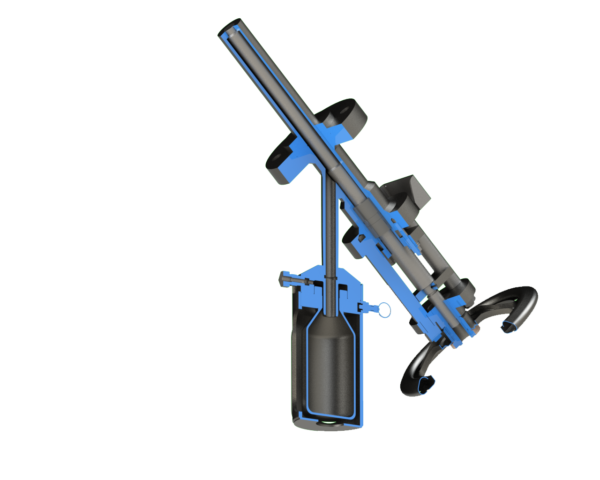

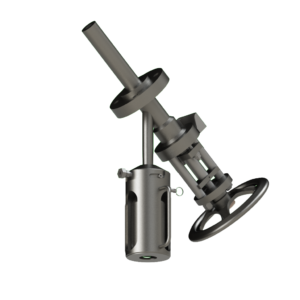

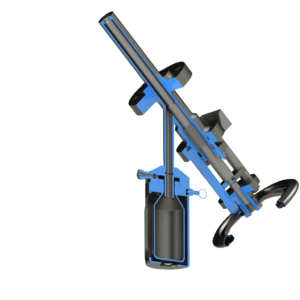

Sampling valve

Sampling valve

To analyse the evolution of the product. For liquids, liquids with solid parts, powders

see moreDN

15 à 150

NPS

1/2 à 6

PN

10 à 50

Class

150 à 300

brand(s)

CONTACT USFunctionnality

For taking samples : in tank, reactor or in-line

Utilization

SERVICE CONDITIONS

High temperature, Low temperature, Abrasion, Corrosion, Vacuum

TYPES OF FLUIDS

Liquids, Liquids with solid particles, Gas, Powder and powdery media, High viscosity fluids

APPLICATIONS

Characteristics

SEALING SYSTEM

- Metal-to-metal sealing with conical piston

- Radial seal with packing, o’rings, etc.

- PTFE-to-metal tightness for service temperature up to 180°C for ball types

OPERATION

- Handwheel,

- Gearbox,

- Dead-man handle,

- Double acting pneumatic actuator,

- Single acting pneumatic actuator,

- Hydraulic actuator,

- Electric actuator

CLOSING DEVICE

- capacitive ball,

- straight piston,

- piston with conical seating surface