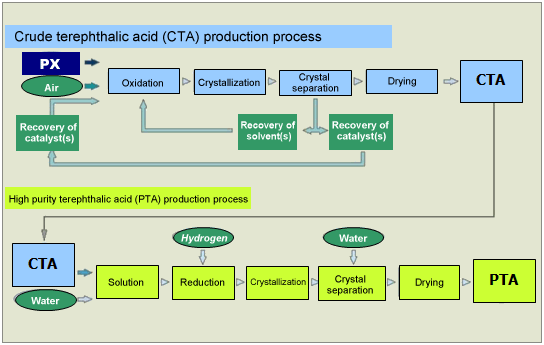

Modern technologies produce purified terephthalic acid by the catalytic liquid phase oxidation of paraxylene in acetic acid, in the presence of air. The process uses manganese or cobalt acetate as a catalyst. The reaction is exothermic, producing water which is removed in a solvent recovery system. Acetic acid from this is returned to the reactor together with the oxidation catalyst. The resulting PTA is purified in a crystalliser where the unreacted xylene and water are flashed off.

It exists several process licensed by : BP (Amoco), Advansa (ICI), Dow (Inca), Mitsubishi, Eastman and Mitsui. The figure below presents the simplified process of Hitachi :